Engineering

Technical capabilities and segment coverage.

Business Segments

Business Segment I - Markets That Accept China Origin

| Product Category | Standards | Common Applications |

|---|---|---|

| OCTG Casing & Tubing | API 5CT / API 5B | Drilling, completion, production & workover |

| Mechanical / Structural | GB / ASTM / EN | Offshore structures, equipment fabrication, load-bearing |

| Line Pipe | API 5L / ISO 3183 | Oil & gas gathering and transmission |

Strategic Mill Partners

Baotou • Hengyang Valin • Dalipal • Fengbao • TPCO

- Reliable production capacity & controlled delivery

- Full steel grade & specification coverage

- Strong QA documentation & certifications

- Superior landed cost competitiveness

Business Segment II - Origin-Compliant via Southeast Asia

Upgradable mother pipes (East Asia) • Heat treatment & premium threading (SEA) • SEA COO • Compliant entry into restricted markets.

| Process | Technical Capability |

|---|---|

| Heat Treatment (Q&T / Normalize / SR) | Controls strength, toughness, fatigue & corrosion resistance |

| Premium Connection Threading | PL-series, PH-series, compatible metal-to-metal seals |

| Inspection & Validation | NDT/EMI, torque & seal testing, hydrostatic; 3rd-party witnessable |

| Traceability & Dossier | Material origin • processing logs • QA data • COO • shipping dossier |

Our Products

OCTG

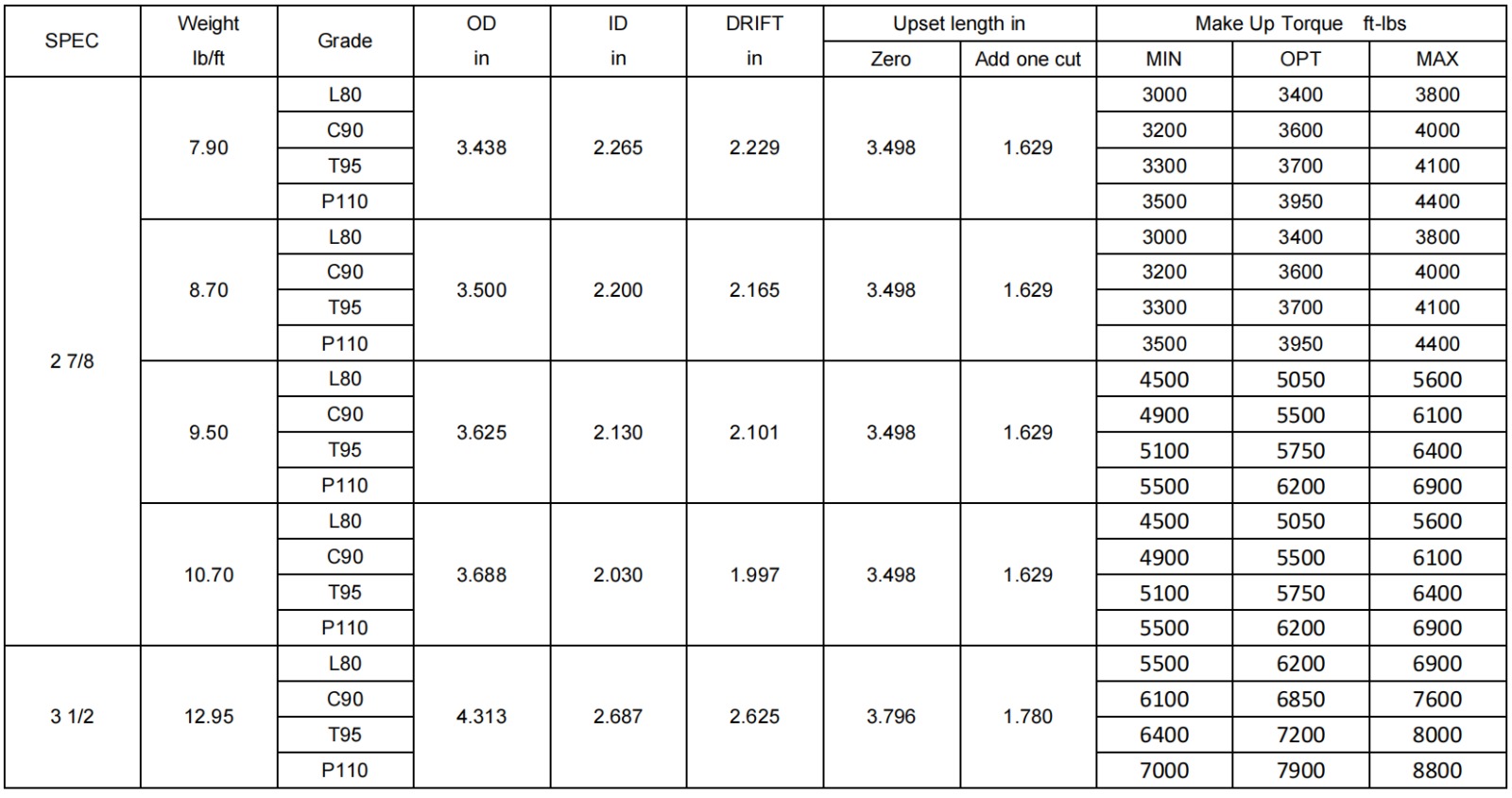

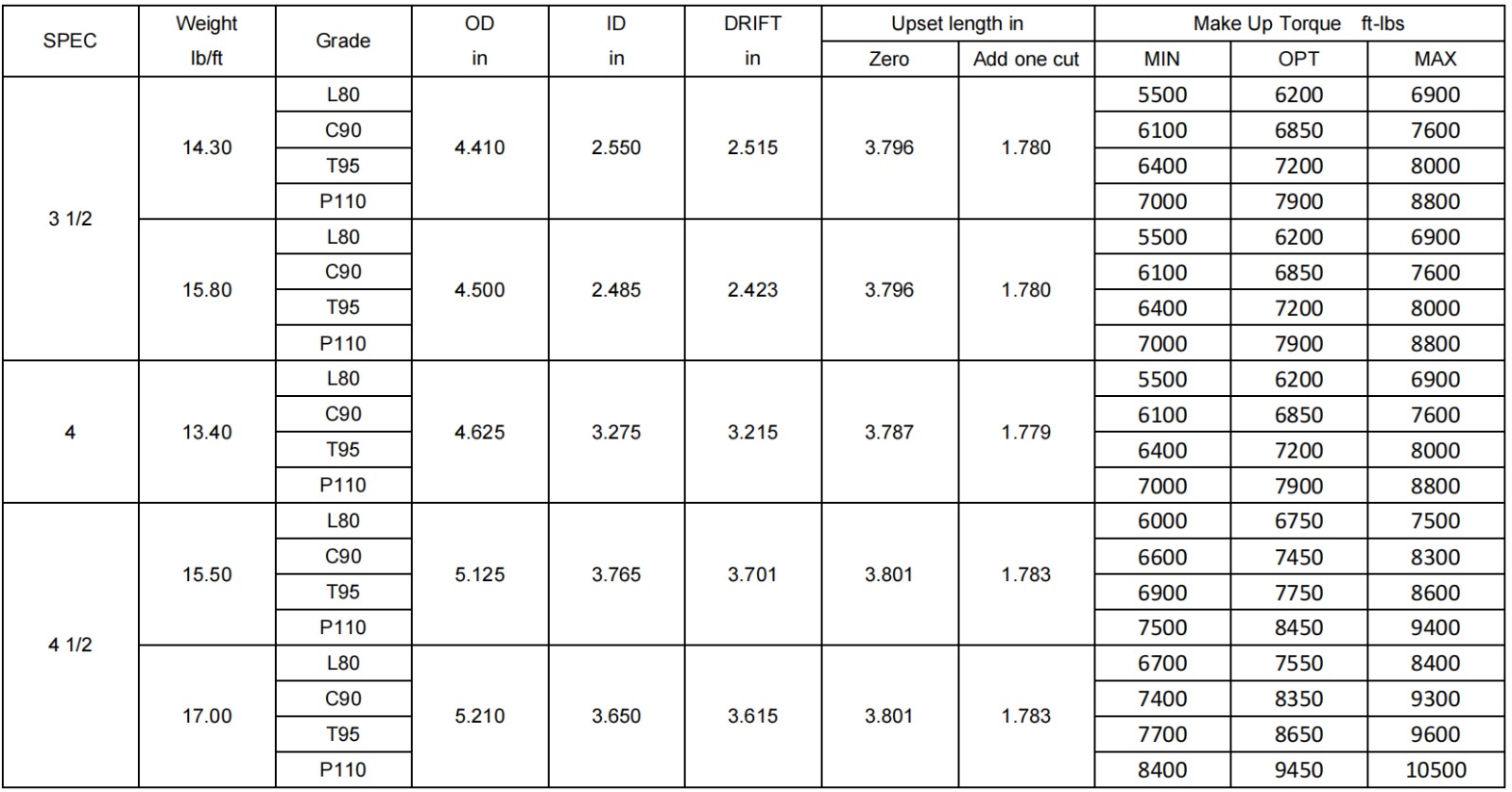

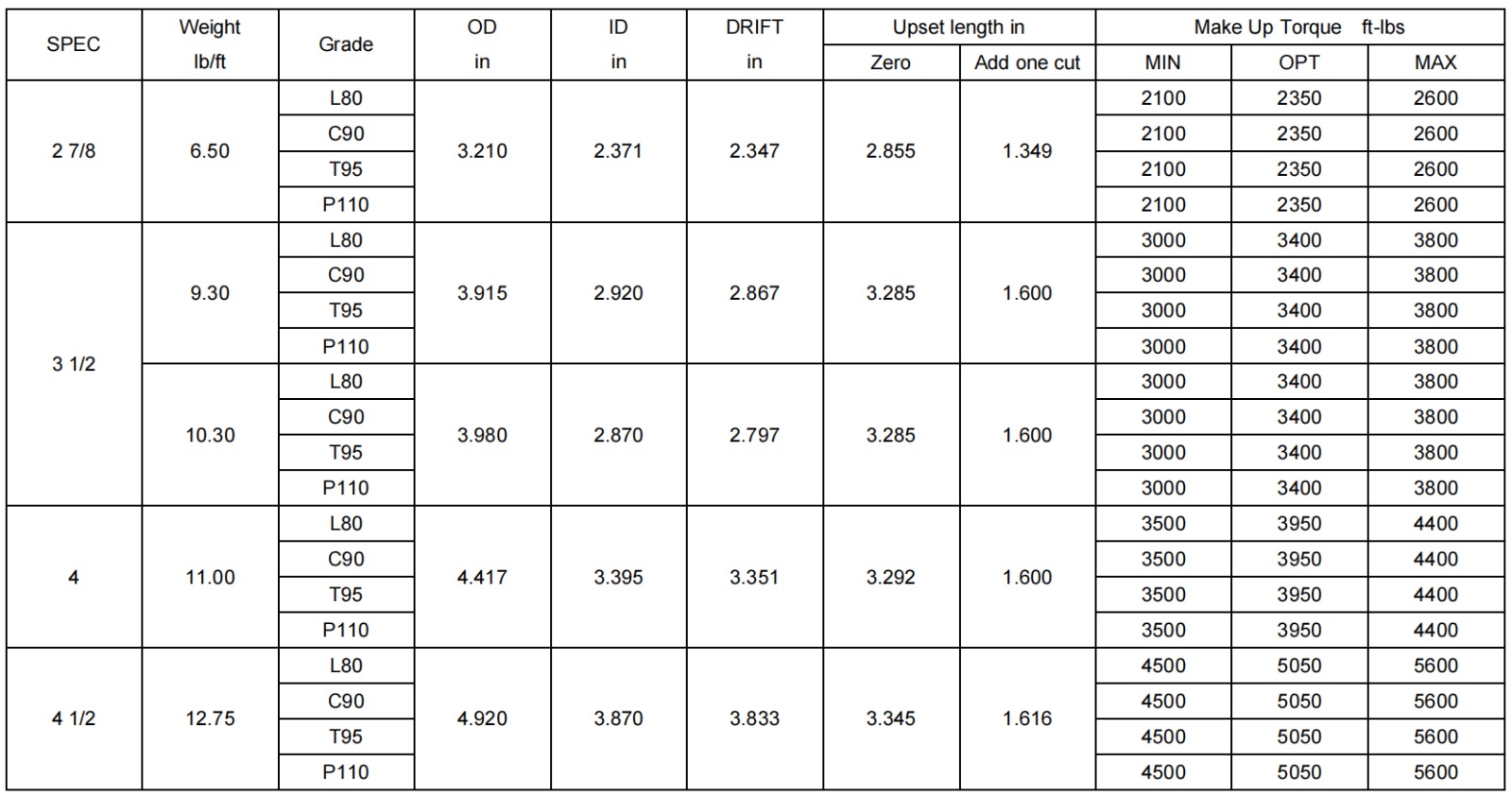

PL6 & PL8 Premium Connection

The PL Two-Step Integral Premium Connection (PL-6 / PL-8) is engineered for reliable makeup, field-service efficiency, and high-performance downhole integrity. Featuring a metal-to-metal gas-tight seal and a low-stress thread profile, the PL-6/8 minimizes galling risk while delivering full 100% ratings in tension, compression, and both internal and external pressure.

This connection is particularly suited for unconventional applications requiring post-fracturing clean-out or drilling through cement and debris. It provides superior seal reliability and structural toughness in deep, high-pressure gas wells, high-intensity fracturing operations, and long-term production strings.

Additionally, we can supply custom extended upset lengths, enabling multiple re-cuts (up to two re-head operations) for extended service life — delivering greater operational flexibility and lower cost per well over the full lifecycle.

The PL system is available in two sizes — PL-6 and PL-8 — offering proven performance across a wide range of completion and production environments.

Performance & Design Highlights

| Feature | PL-6 / PL-8 Advantage |

|---|---|

| Thread Form | Two-step integral, low-stress, galling-resistant |

| Seal Type | Metal-to-metal, gas-tight seal |

| Ratings | 100% tension / compression / internal & external pressure |

| Field Handling | Simple make-up, repeatable sealing, low galling risk |

| Best Use Cases | HP gas wells, frac programs, debris & cement drill-outs |

Technical Data Sheets

OCTG - Casing, Tubing & Accessories

- Product: Oil Country Tubular Goods (OCTG)

- Standard: API 5CT

- Connections: API (STC/LTC/BTC) & Premium (PL-6/PL-8)

- Dimensions: 1/2" - 24"

- Lengths: Single Random (4-7m) and Double Random (8-14m)

- Grades Available: J55, K55, L80-1, N80, N80Q, C90, T95, P110, Q125

- Surface: Mill varnish / Black

- Certification: 3.1 per EN 10204

Linepipe/Mechanical structure pipe

Seamless Carbon Steel Linepipe

- Product: Seamless carbon steel tubes for process and linepipe

- Standard: API 5L, ASTM A106, EN10216, ASTM A333 (low temp)

- Dimensions: 1/2" - 24"

- Lengths: Single (4-7m) and Double Random (8-14m)

- Delivery Condition: Bevelled ends for O.D. > 60.3 mm

- Materials: Gr. B, X52, A106 Gr. C, P265GH, Gr. 6 LT45, P355 (low temp)

- Surface: Mill varnish

- Certification: 3.1 per EN 10204

Seamless Carbon Steel Tubes (Mechanical / Structural / Pressure)

- Product: Seamless carbon steel tubes for mechanical engineering, construction & pressure service

- Standards: EN 10297-1, EN 10210-1/2, EN 10216-1/3

- Dimensions: 10.2 – 1.6 mm • 660 – 100 mm

- Lengths: Single (4-7m), Double Random (8-14m)

- Materials: P355N TC1, S355J2H, E355 N

- Surface: Black, non-oiled

- Certification: 3.1 per EN 10204

Seamless stainless pipe

Seamless Stainless Round Tubes - Cold Finished

- Product: Seamless stainless round tubes, cold-finished

- Standards: ASTM/ASME A/SA213, ASTM A269, EN 10216-5 TC1/TC2

- Dimensions: 6.35 – 0.89 mm • 139.7 – 4 mm (other on request)

- Lengths: 5-7m (custom fixed lengths available)

- Delivery: Bright annealed / Annealed & Pickled / Polished (Grit 240)

- Material Nos.: 1.4301/1.4307, 1.4401/1.4404, 1.4541, 1.4571

- Equivalent Grades: TP304/304L, TP316/316L, TP321, TP316Ti

- Certification: 3.1 or 3.2 per EN 10204

- Origin: EU & Non-EU

Seamless Stainless Round Tubes - Hot Finished

- Product: Seamless stainless round tubes, hot-finished

- Standards: ASTM A312 / ASME SA269 / EN 10216-5 TC1/TC2

- Dimensions: 33.4 – 6.35 mm • 323.9 – 9.52 mm (other sizes on request)

- Lengths: 5-7m (special lengths optional)

- Delivery: Hot-finished, annealed & pickled

- Material Nos.: 1.4301/1.407, 1.4401/1.4404, 1.4541, 1.4571

- Equivalent Grades: TP304/304L, TP316/316L, TP321, TP316Ti

- Certification: 3.1 or 3.2 per EN 10204

- Origin: EU & Non-EU